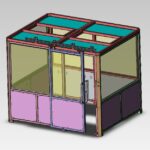

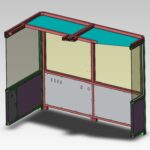

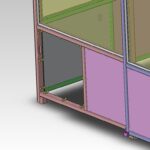

The customer needed a small clean room for a specific manufacturing process. The placement of the clean room was very specific and had volume constraints from the adjacent work area. Once a specific internal machinery layout was determined the supporting electrical/pneumatic needs were incorporated into the design for a clean installation.

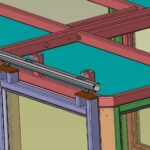

The design used primary steel tube that could be pre-fabricated, powder coated and assembled at the customer’s site.