Process Design

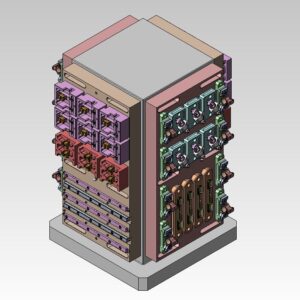

From large precision machine components to small hypo-tubes we have been involved in the manufacturing of many parts and assemblies across many industries. If you need support in the NPI phase or a process review of an already established product we can help. We can support process development through engineering reviews, process modeling and drawing creation, or even reviewing or auditing your current manufacturing process to search out new opportunities.

DFM Review

Many times a design looks perfect as it’s being spun around within a CAD system or detailed on a sheet of paper. But as soon as you start producing chips things get expensive real quick. The small details will quickly surface to the top of the action item list to be resolved. Was this detail missed or is it a manufacturing challenge that hasn’t been resolved yet? Do you need to go to the customer and negotiate for more tolerance? Do you want the design internally reviewed prior to starting conversations with a manufacturer? While Engineering Design Reviews are a necessary tool, they are typically not reviewed through the lens of the manufacturer.

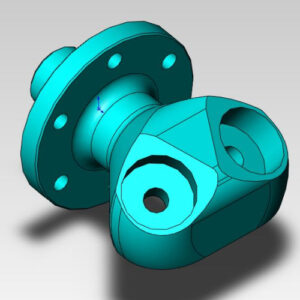

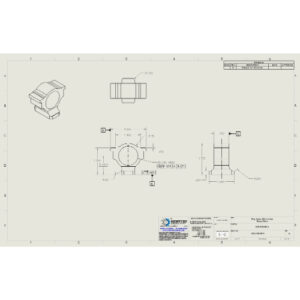

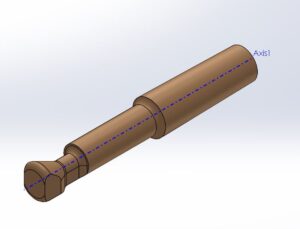

Process Models/Drawings

When manufacturing complex parts, process models and drawings can quickly define the success and failure of a project. All of the steps need to be planned, defined and appropriately controlled from the raw stock to the finished part. A handful of machining operations can quickly turn into a volume of mechanical drawings required to produce the part, which in turn becomes a heavy resource burden to keep up with any rapid changes. We can support and increase your process development by taking on the process modeling and drafting tasks. This can free up your engineering team to address other more critical tasks.

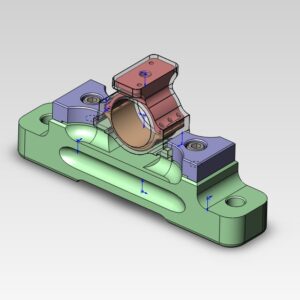

Tooling Fixture Design

Tooling and part set-up can really differentiate the success of a machined part. All too often fixturing is glanced over as ‘good enough’ but then folks are surprised when unforeseen challenges arise in part quality. Having a solid foundation of the manufacturing processes is only part of the process to creating a good part. Having solid, rigid and repeatable fixturing is key to developing a successful manufacturing process. We have supported complex single part production to high volume and high density part fixturing.

Custom Gaging

Complicated parts and assemblies are even more challenging to evaluate. Often custom tooling and unique inspection methods need to be developed in order to qualify the assembly; tasks which are usually left up to the supplier to develop. From evaluating the design specifications, developing and documenting the inspection plan, to supporting the implementation of the inspection techniques we can support your critical process validation needs.